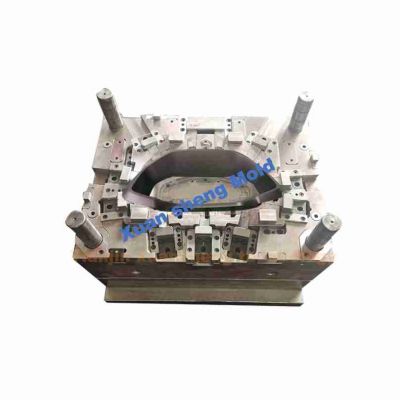

auto door handle parts mould

| Product Name | Taiwan's technology make plastic auto door handle parts mould of automotive injection mold |

| Mould material | P20,NAK80,S50C,1.2738,1.2343 etc. |

| Cavity | Multi |

| Runner | Hot |

| Mould Base Brand | LKM, etc |

| Mould Life | 300,000~1,000,000 shots |

| Plastic Material | PP, ABS etc |

| Tolerance | 0.02 mm |

Taiwan's technology make plastic auto door handle parts mould of automotive injection mold

Our company has made the plastic auto door handle parts mould of automotive injection mold.

This mould has hot runner systerm,and it has two cavity and two sliders. It's hot runner brand is YUDO.

This mould size is 500*500*466 mm.Its weight is about 553 kg. The mold cavity and core material is 1.2738.

The mold slider material is 1.2343. It has one point direct hot nozzle. This product material is PP+TD20.

This product is the internal structure of the car door, and the appearance is polished.

The size of this product is relatively large and requires assembly, so it is necessary to prevent product deformation and ensure the size of the product.

We conduct mold flow analysis on the product before making the mold, that is, perform product filling analysis on the product.

We generally make several plans. Through comparison, we will choose the best plan to minimize product deformation,

where the product is trapped, and pre-exhaust treatment, and so on.

With mold flow analysis as a reference, the number of mold repairs can be reduced.

Looking forward to cooperating with you.