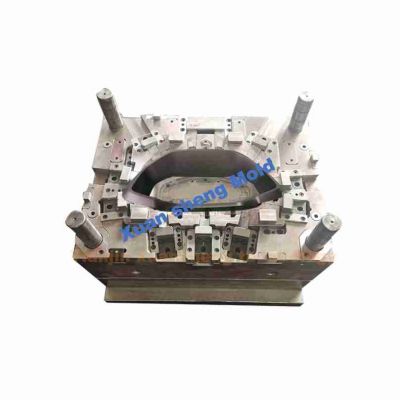

car charcoal canister mold

| Product Name | Taiwan's technology make plastic Auto carbon canister mould of automotive injection mold |

| Mould Base | P20,P20HH,H13,2738,NAK80,2316 etc. |

| Cavity | Single/ Multi |

| Runner | Hot / Cold |

| Mould Base Brand | LKM, HASCO, DME, self-control etc |

| Mould Life | 300,000~1,000,000 shots |

| Plastic Material | ABS, PC, PMMA, PP, PBT, PE, Nylon etc |

| Tolerance | ±0.02 mm |

Taiwan's technology make plastic Auto carbon canister mould of automotive injection mold

This is the plastic Automobile carbon canister housing injection mould.This mould has five sliders,four lifters

and the mould insert material are all H13.This mould also has hot runner.And it has three needle valve points.

This mold size is 750*1050*780mm and its weight is 3820KG.This mold hot runner system is YUDO and has three open direct needle valve.

This set of molds has five sliders. Due to the large volume of the slider, the order of mold opening of each slider must be controlled,

so each slider is driven by the oil cylinder.In this way, in the injection molding process, the injection molding machine can control the oil cylinder

to achieve the sequence of controlling the opening and closing of the slider.

The material of the plastic product is PA6+GF15. In order to ensure the mold production rate, steel with high corrosion resistance and hardness must be used.

The way the mold is ejected is to use a push plate to prevent the product from being too high, causing the phenomenon of white topping and convexity of the product.

Looking foward to providing you with better service.