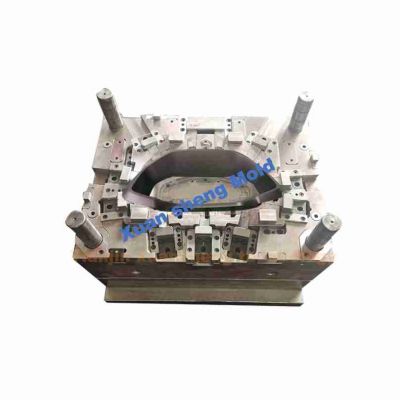

car seat headrest part mould

| Product Name | Taiwan's technology make plastic car seat headrest part mould and automotive injection molding |

| Mould material | P20,S50C,1.2343 etc. |

| Cavity | Multi |

| Runner | Hot |

| Mould Base Brand | LKM, etc |

| Mould Life | 300,000~1,000,000 shots |

| Plastic Material | PA6 etc |

| Tolerance | 0.02 mm |

Taiwan's technology make plastic car seat headrest part mould and automotive injection molding

Our company has made the plastic car seat headrest part mould and automotive injection molding.

The product is composed of two parts: a guide rod and a guide rod insert.Their material is PA6.

The car seat headrest guide mould size is 400*550*385mm.The mold weight is about 465KG.

The mold has two cavity and two sliders.The mold core ,cavity,sliders material are all 1.2343 which needs to do heat treatment.

Since the slider on the sky side has a relatively large stroke, it is necessary to draw out the slider insert by an oil cylinder with a battery valve.

The car seat headrest guide rod insert mould is 400*350*365mm.The mold weight is about 363KG.

The mold has four cavity and two sliders.The mold core ,cavity,sliders material are all 1.2343 which need to

do heat treatment too.The product surface requirement texture.

These two moulds both have hot runner systerm.It's brand is YUDO.

Hope to providing you with better service !