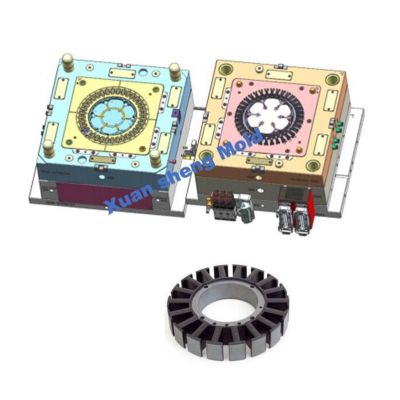

Stator insulation precision overmould insert injection molding

| Product Name | Stator insulation precision overmould insert injection molding |

| Mold Base | S136,8407,1.2311,SKD61 etc. |

| Cavity | 1*1 |

| Runner | Hot runner |

| Mold Base Brand | LKM, HAS CO, DME, self-control etc |

| Mold Life | 500,000 shots |

| Plastic Material | PBT+GF30 |

| Mold package | Wooden box |

| Tolerance | 0.02 mm |

Stator insulation precision overmould insert injection molding

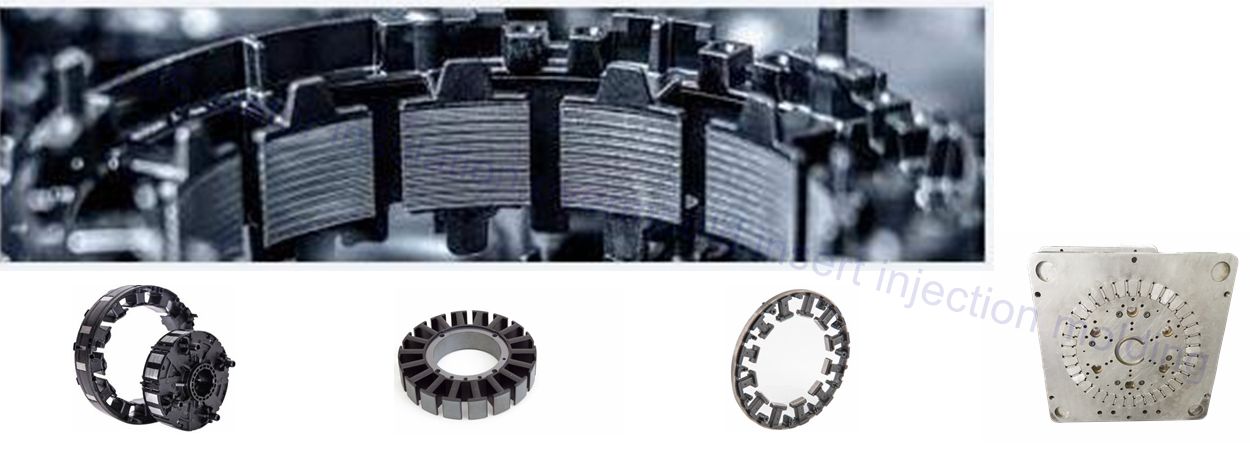

Our company made many kinds of stators insulation precision overmould and done insert injection molding.

I will introduce the stator insulation precision overmould and insert injection molding here.

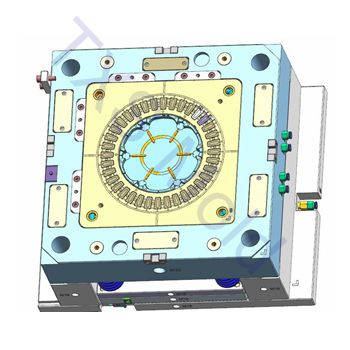

This overmould has one cavity and has hot runner system which brand is YUDO.

This product generally use the PBT+GF30. So the overmould material should use SDK61 or S136

and so on. This overmould size is 600*620*540, and its weight is 1012 kg.

The overmould most important thing is to solve the feeding balance, to ensure the size of

each angle of the product is consistent.

When insert injection molding, we should put the insert into the mold first.

So we should ensure the mold parts dimension in the tolerance.

Before the insert injection molding, we should do the mold flow analysis first.

Welcome your inquiry.

Thank you.