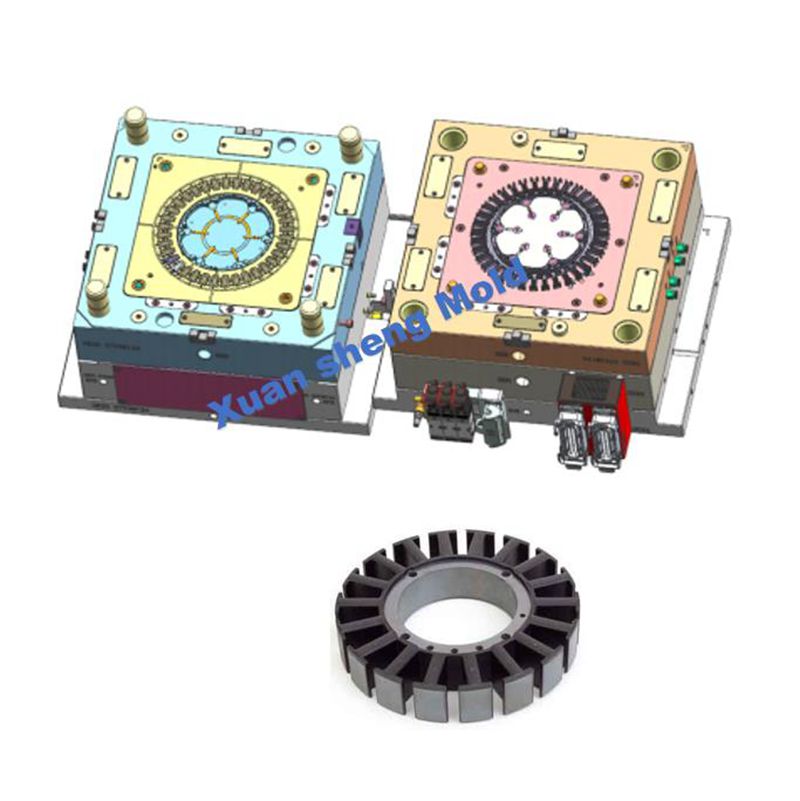

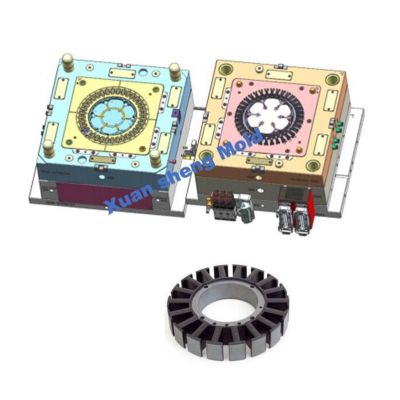

plastic insulating stators and rotors overmoulding

| Product Name | Taiwan's technology plastic insulating stators and rotors overmoulding of overmoulding |

| Mold Material | SKD61,8407,S136 etc. |

| Cavity | Multi/single |

| Runner | Hot runner and cold runner |

| Mold Base Brand | Hasco / Lkm |

| Mold Life | 500,000 shots |

| Plastic Material | PBT+GF30 |

| Mold package | Wooden box |

| Tolerance | 0.02 mm |

Taiwan's technology plastic insulating stators and rotors overmoulding of overmoulding

The plastic insulating stators and rotors overmoulding is a precision moulding.

The mold needs to cooperate with the silicon steel sheet very reasonably.

Too tight or too loose, and the product will fail.

If the mold and silicon steel inserts are too tight, it will cause difficulty in ejecting the product.

In injection molding production, it will cause the inserting time to be too long and increase the injection molding time.

At the same time, it will affect the life of the mold.

If the mold and the silicon steel insert are too loose, the plastic product will have burrs and the product will be unqualified.

Because the hardness of the insert is very high, the material of plastic products is generally PA6+GF30.

The mold needs to use very hard, high-quality, corrosion-resistant steel.

The plastic insulating stators and rotors moulds are very precision moulds. The mould material we usually choose the

SKD61 which should be done heat treatment HRC 50~52°. This steel also has the function of corrosion resistance.

In injection molding production, the silicon steel sheet inserts need to be put into the mold, and then injection molded.

Therefore, the requirements for ensuring the size of silicon steel inserts are very high.

Hope to provide you with better service !

Thank you !