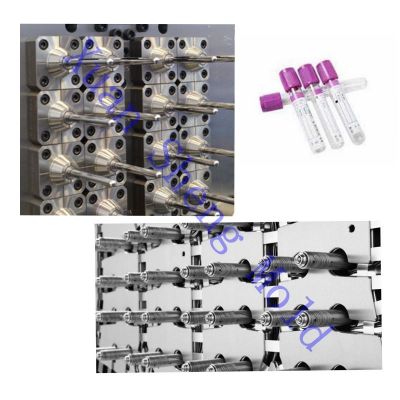

plastic medical device mold

| Product Name | Taiwan's technology make plastic medical device mold and injection molding medical devices |

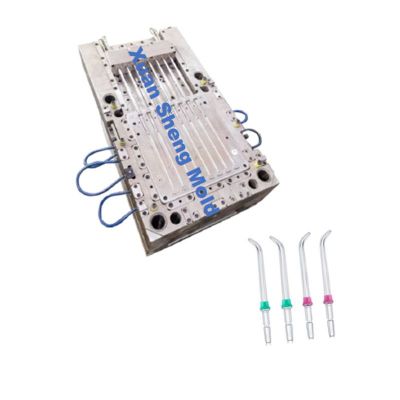

| Mould Material | P20,P20HH,H13,2738,NAK80,2316 etc. |

| Cavity | Single/ Multi |

| Runner | Hot / Cold |

| Mould Base Brand | LKM, HASCO, DME, self-control etc |

| Mould Life | 300,000~1,000,000 shots |

| Plastic Material | ABS, PC, PMMA, PP, PBT, PE, Nylon etc |

| Tolerance | 0.02 mm |

Taiwan's technology make plastic medical device mold and injection molding medical devices

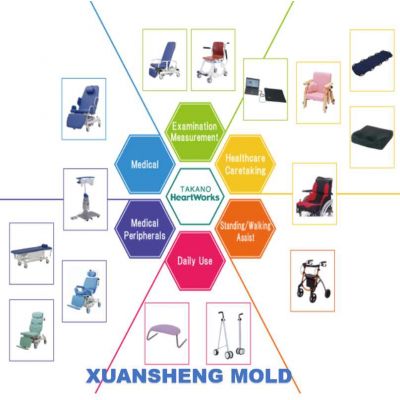

Our company has made many kinds of plastic medical device molds.For example, there are medical injection pumps,

nutrition pumps, gastric lavage machines, infusion pumps, suction pumps and other medical equipment plastic parts molds.

The appearance of medical device products is mostly dermatoglyph, and the requirements for appearance are very high.

There should be no scratches and assembly dislocation.

There are probably several methods for processing the texture of the mold: 1. Sandblasting; 2. Chemical corrosion; 3. Electro-discharge machining.

However, most medical device product shells have fine lines on the dermatoglyph surface.

Of course, in addition to the exterior parts, there are many small parts inside, and the assembly size of each part is very important.

A major feature of medical device molds is that there are more mold sliders and inclined top structures.

Looking foward to providing you with better service.