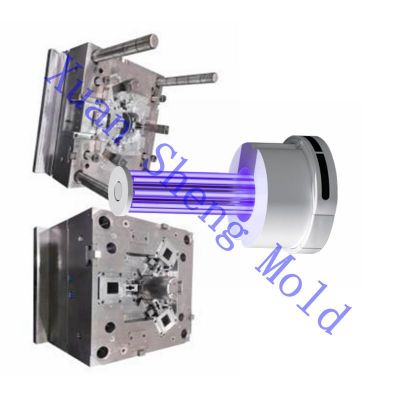

Electric toothbrush precision plastic mold

| Product Name | Electric toothbrush precision plastic mold |

| Mold Base | S136,8407,1.2311 etc. |

| Cavity | 1*8,1+1 |

| Runner | Hot runner/ cold runner |

| Mold Base Brand | LKM, HAS CO, DME, self-control etc |

| Mold Life | 1,000,000 shots |

| Plastic Material | PA6,PC+ABS |

| Mold package | Wooden box |

| Tolerance | 0.02 mm |

Electric toothbrush precision plastic mold

Electric toothbrushes are generally divided into the following two categories:

1. Rotation: Rotary transformation, also known as mechanical toothbrush or lazy toothbrush,

use the built -in electrical machine to make the brush head a normal brushing movement.

2. Sound vibration type: Use the body's electronic chip to generate high -frequency sound

wave vibration. The vibration method is the colleagues who can quickly complete the

brushing movement of the dental brushing movement above and down the direction of

the vertical fuselage. The air bubbles, the air pressure generated during the bubble burst

can enter the teeth, effectively clean up the teeth and various residues.

This electric toothbrush made by our company is mainly composed of 7 pieces of plastic parts.

Let me introduce the connecting rod precision plastic mold for you.

This precision mold has two cavities, and its mold material is 718H. The mold size is 250*250*220,

and its weight is 185 kg.

Because the product is relatively small, multiple parts of this precision plastic mold used precision discharge

spark processes.

The ejector pins of the product are also very fine, and the requirements for wire cutting the ejector pinholes are very high.

Our company has world-class mold processing equipments and detecting equipments.

We also have 100k precision injection molding machines.

Our company has the product assembly line manufacturer partner.

We could provide the precision plastic mold and precision molding services.

Welcome your inquiry.

Thank you.